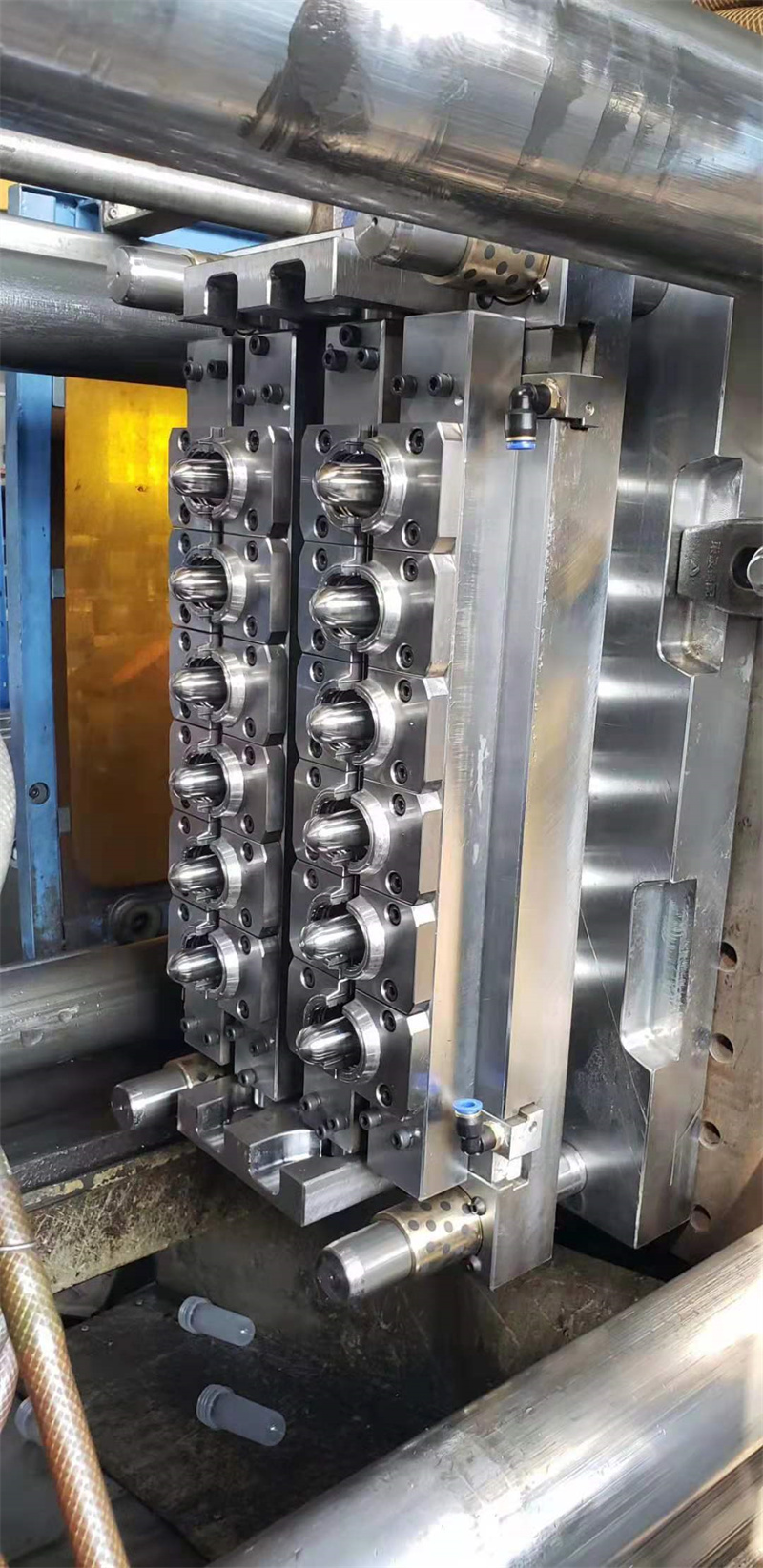

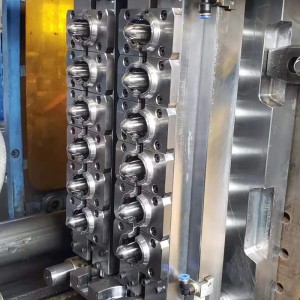

12 Cavity PET Preform Mold

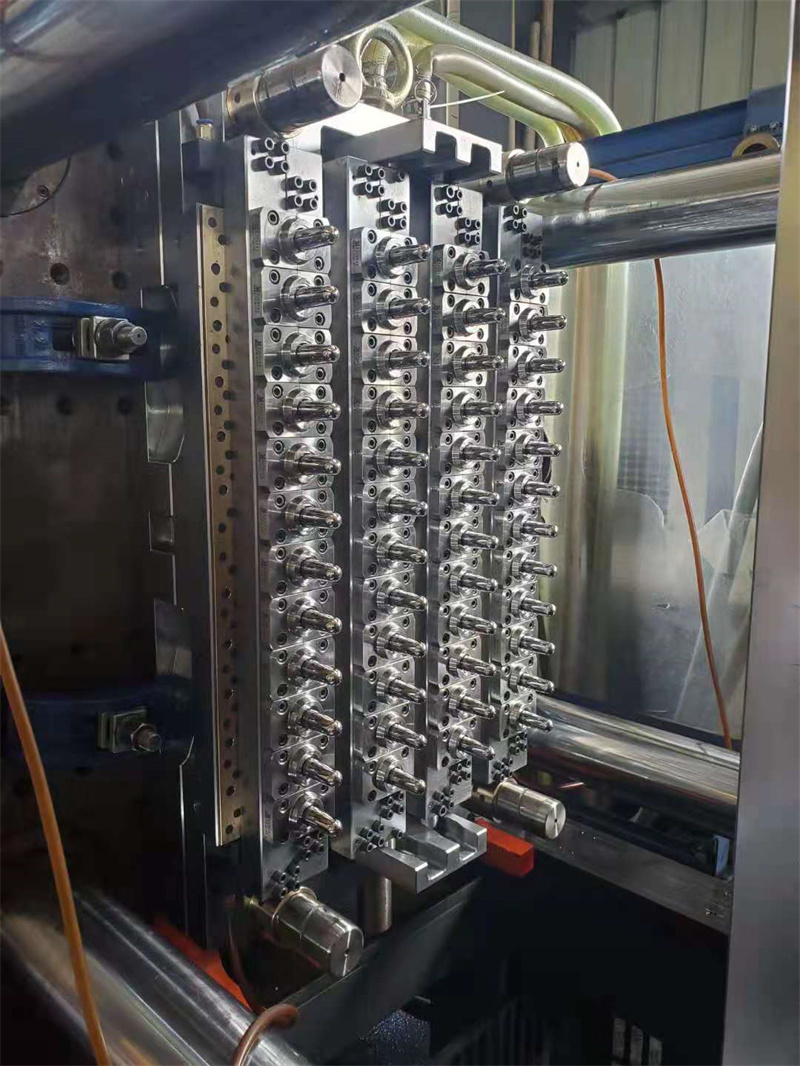

I-48-cavity pin valve PET preform mold

1. Umgijimi oshushu wamkela inkqubo yokulawula i-PID, ebonakaliswe ngokulungiswa ngokuzenzekelayo kunye nemisebenzi yokukhusela ngokuzenzekelayo, enokwandisa ubomi benkonzo yesixhobo sokufudumala kombane;

-Iqondo lokushisa lilawulwa ngaphakathi kwe-1 ° C ukuqinisekisa ukuba izinto eziluhlaza azitshiswa kumgijimi oshushu, kwaye izinga lemveliso eligqityiweyo linokufikelela ngaphezu kwe-99%;

-Uyilo olutsha lombhobho lwenza ukuba kube lula ukubumba ukubumba, indawo enombhobho, indawo yokufudumeza, indawo yokugquma ubushushu, kunye ne-thermocouple inokutshintshwa ngokulula ngaphandle kokuqhawula ukungunda, okuluncedo ukunciphisa ixesha lokuphumla kunye nokugcina iindleko zokugcinwa. .

2. Inkqubo yokupholisa

-Ijelo lamanzi lokupholisa elijikelezayo lenza isiphumo sokupholisa sibe namandla.

-Umjelo wamanzi okupholisa kwizibuko elinemisonto kunye nesilayidi sonyusa umphumo wokupholisa.

-Iplati yokusabalalisa eyilwe ngokugqwesileyo, amanzi okupholisa angangeniswa ngokulinganayo kwi-cavity nganye, kwaye zonke iipreforms zinokupholiswa ngokufanelekileyo ngokulinganayo kwaye ngokukhawuleza.

3. Imbaleki eshushu

- Umgijimi oshushu kunye nokusebenza kakuhle kokulinganisa uqinisekisa ukuhamba kunye noxinzelelo lwe-PET inyibilika kuzo zonke iimbombo zifana.

-I-PET melt channeling inciphisa ilahleko ye-chear kunye ne-IV kwaye ivumela i-PET inyibilike ukuba ihambe ngokulinganayo kuyo yonke imingxuma.

- Ukusasazwa kobushushu obulungileyo kugcina umxholo we-acetaldehyde (AA) kuzo zonke iimbombo zizinzile.impahla

I-Custom Material 632: Ingcono kune-FS136 enomxholo ophezulu we-nickel kunye ne-chromium.

Ukuqina, ukuxhathisa umhlwa, kunye nesiphumo sokwenza mhlophe ngokucacileyo kuyaphuculwa.

Isiseko sokubumba senziwe nge-HRC 38 ~ 40 insimbi engenasici okanye i-P20 (i-pre-hardened).

2. Uyilo lwesitaki sohlobo lweSelfLock

Phambi kokuvala ukungunda, umthungo wokwahlula uvalwa endaweni ngendandatho yokutshixa ukunciphisa ukunxitywa komgca wokwahlula kwicala lomngxunya kunye necala elingundoqo, ngaloo ndlela ukwandisa ubomi obungenaburr bomgca wokwahlula.

Intshayelelo kwiMveliso yokuMngunda

| Uhlobo | Ubude(mm) | Ububanzi(mm) | Ukutyeba(mm) | Ubunzima(kg) |

| 6 Umngxuma | 650 | 270 | 490 | 600 |

| 8 Umngxuma | 480 | 360 | 490 | 595 |

| 12 Umngxuma | 610 | 360 | 490 | 755 |

| 16 Umngxuma | 740 | 360 | 510 | 960 |

| 24 Umngxuma | 790 | 500 | 510 | 1415 |

| 32 Umngxuma | 800 | 580 | 510 | 1600 |

| 48 Umngxuma | 1120 | 600 | 560 | 2640 |

| 64 Umngxuma | 1380 | 600 | 610 | 3545 |

| 72 Umngxuma | 1170 | 800 | 610 | 4010 |

| 96 Umngxuma | 1230 | 960 | 610 | 5050 |

Idatha engentla isekelwe kwi-preform ye-16g enentamo ye-PCO.

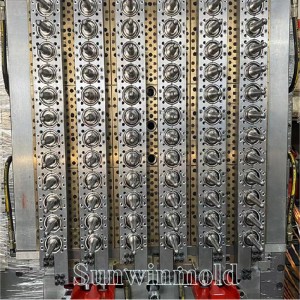

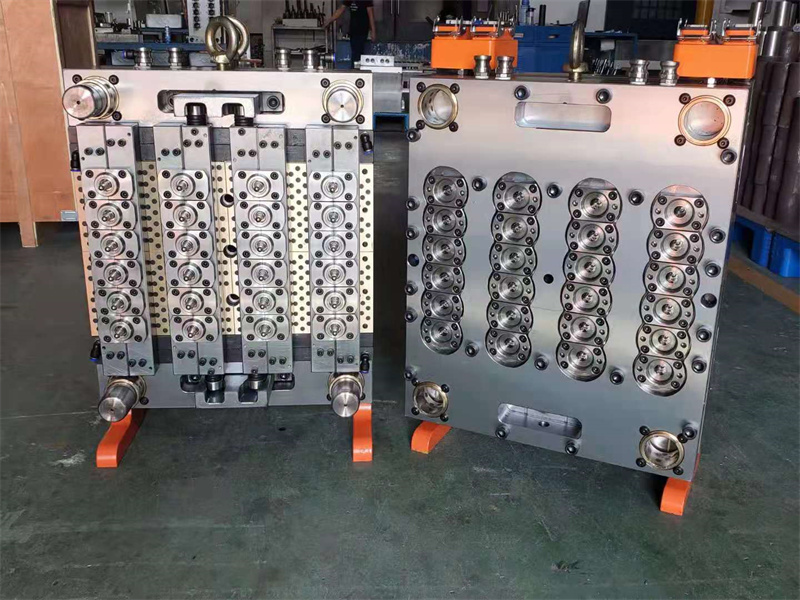

I-48-cavity air-sealed PET preform mold

1. Iimpawu zokungunda:

1. Sisebenza ngokukhethekileyo ekuveliseni iimbumba zeenaliti zeenaliti, ezingadingi ukusika ngesandla.

2. Ukusetyenziswa kwenkqubo yomqhubi oshushu ophambili uqinisekisa ukuba ixabiso le-AA lemveliso liphantsi.

3. Uyilo olufanelekileyo lomjelo wamanzi okupholisa luqinisa isiphumo sokupholisa somngundo kwaye lunciphise ngempumelelo umjikelo wokubumba inaliti.

2. Ukukhethwa kwezinto:

1. Iinxalenye eziphambili ze-mold zenziwe ngezinto eziphathekayo ze-S136 (eSweden-Sabak).

2. Isiseko se-mold material yamkela izinto ze-P20 ezivela ngaphandle kunye nonyango lwe-electroplating, oluphucula ukuxhathisa kwe-corrosion ye-mold kunye nokwandisa ubomi benkonzo ye-mold.

3. Ukunyangwa kokushisa kwamacandelo kucutshungulwa kwisithando somlilo esiphuma ngaphandle kweJamani, kwaye ukuqina kwamacandelo kuqinisekisiwe ukuba kwi-HRC45 ° -48 °.

4. Izixhobo zokusebenza ezikwinqanaba eliphezulu:

Inkampani iye yazisa inani lezixhobo zoomatshini ezisuka eUnited States naseJapan, njengamaziko omatshini, i-CNC lathes, i-EDM, njl., Ukuqinisekisa ukuchaneka kwe-machining yamacandelo kunye nokwenza ukuba iindawo zibe nokutshintshiselana okulungileyo., impazamo yobunzima bungaphantsi kwe-0.3g, i-2-5 i-molds inokuveliswa ngomzuzu omnye, kwaye ubomi benkonzo bunokufikelela kwi-2 yezigidi ze-mold times.

24 umgodi preform ngundo

Isakhiwo esitsha sokubumba i-preform esaphandwa ngokuzimeleyo kwaye siphuhliswe sinokuphelisa ngokupheleleyo ubuninzi bezinto ezingalunganga zokubumba ezidlulileyo, kwaye zinokufikelela ekugxineni okuphezulu okuchanekileyo kunye nobomi obude bokubumba, kwaye inokuqhuba umgangatho weendawo ezahlukeneyo zokubumba kunye nemveliso yobuninzi.Iimbumba zethu ziqinisekisa ukuba ukuhlukana kodonga lwetyhubhu engenanto ingaphantsi kwe-0.05mm, kwaye impazamo yobunzima ingaphantsi kwe-0.3g.I-2-5 i-molds inokuveliswa ngomzuzu omnye, kwaye ubomi benkonzo bunokufikelela kwi-2 yezigidi ze-mold times.Umngundo unemingxuma engama-96 ubuninzi.

I-48-cavity air-sealed PET preform mold

1. Amava obugcisa kunye nobugcisa kwi-preform mold cavities ukusuka kwi-1 ukuya kwi-96 cavities.

2. I-mold ye-preform isebenzisa isofthiwe ye-CAD ukuyila i-preform shape ngokwebhotile ukuqinisekisa umgangatho wokubumba webhotile.

3. Izinto zokuvula intambo ye-preform mold yenziwe ngentsimbi ye-nitrided evela ngaphandle, eyenziwe ngokwemigangatho yamazwe ngamazwe, enobunzima obuphezulu, intambo nganye ifakwe umoya, kwaye inobomi obude benkonzo ngaphandle kokuguqulwa.

4. Isiseko se-mold ye-preform kunye ne-cavity yenziwe ngentsimbi enganyangekiyo kwi-corrosion, ehlala ixesha elide.

5. Umngundo we-preform wamkela uyilo oluphambili lwembaleki eshushu, ukuze indawo nganye ikwazi ukulawulwa ngokuzimeleyo kobushushu, ifudunyezwe, kwaye iqondo lobushushu lifane.

6. Isango lokusikwa-free isango preform ngundo, ukonga abasebenzi kunye nemathiriyeli ekrwada.

7. Ubushushu bombhobho wembaleki oshushu bulawulwa ngokwahlukileyo.(Ukusombulula ingxaki yomhlophe kunye nomzobo wocingo ezantsi ngexesha lenkqubo yokuvelisa).

8. Inaliti-valve self-locking i-preform mold: i-core nganye, i-cavity, i-self-locking i-self-locking, i-eccentricity adjustable, ukunciphisa i-eccentricity, iqinisekisa ukugxila kwemveliso, ukuchaneka okuphezulu.Umngundo unobomi obude benkonzo.

9. Isampula yenkxaso kunye nokucwangciswa komzobo, ukubonelela ngophuhliso lwemveliso entsha, inkonzo yokumisa enye yokulungiswa kwenaliti yokubumba!

12 umngxuma PET preform ngundo

1. Ukungena ngaphandle kwe-S136 intsimbi yentsimbi, ingundoqo, kunye nentamo edibeneyo isetyenzisiweyo, kwaye ukuqina konyango lokushisa kunokufikelela kwi-HRC 48-50;zonke iifomworks ziphathwa ubushushu ngobulukhuni be-HRC 30-35.

2. Itekhnoloji yoyilo lokungunda olukwinqanaba eliphezulu: Umgodi ngamnye uzitshixa ngokuzimeleyo, usebenzisa i-SYATEM yaseJapan echanekileyo.Ukuqinisekisa umlinganiselo ophantsi womzimba kunye nokuchaneka kwemveliso.Idayiti nganye inezifakelo zamalungu ahlala ehlala atshintshana.Ukuze siphucule kwaye sifezekise ukusebenza kakuhle kwemveliso, sihlala siyila eyona nkqubo yokupholisa, kwaye sinokufanisa umatshini wokupholisa kwisikhunta ngasinye.

3. I-valve ye-valve eshushu ehamba phambili kunye nechanekileyo kunye nomlawuli wokushisa uqinisekisa ukuthembeka kwemveliso kunye nokuhanjiswa kokukhanya okuphezulu kunye nokukhanya kwemveliso.

4. Isikhunta se-sliding senziwe ngobhedu, umzimba webhotile udibana nomgangatho wokhuseleko lokutya, kwaye ubomi besikhunta buqinisekisiwe ukuba bube ngaphezu kwezigidi ezi-3 amaxesha.1.Iimpawu zokungunda:

1. Sisebenza ngokukhethekileyo ekuveliseni iimbumba zeenaliti zeenaliti, ezingadingi ukusika ngesandla.

2. Ukusetyenziswa kwenkqubo yomqhubi oshushu ophambili uqinisekisa ukuba ixabiso le-AA lemveliso liphantsi.

3. Uyilo olufanelekileyo lomjelo wamanzi okupholisa luqinisa isiphumo sokupholisa somngundo kwaye lunciphise ngempumelelo umjikelo wokubumba inaliti.