Ukungunda okuNceda ngerhasi

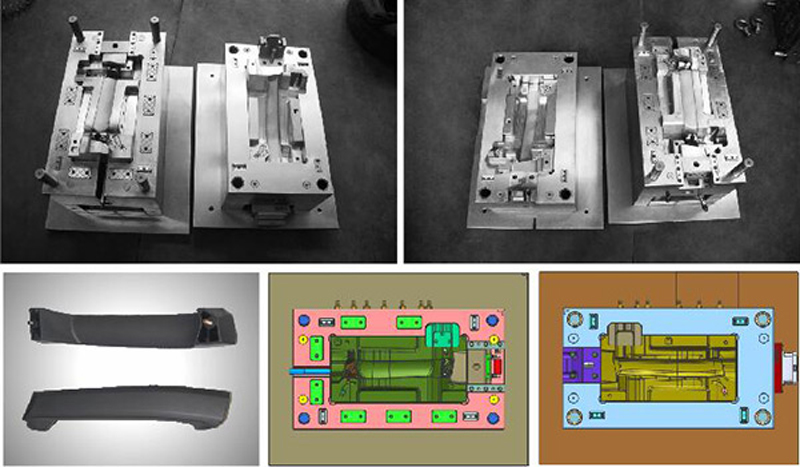

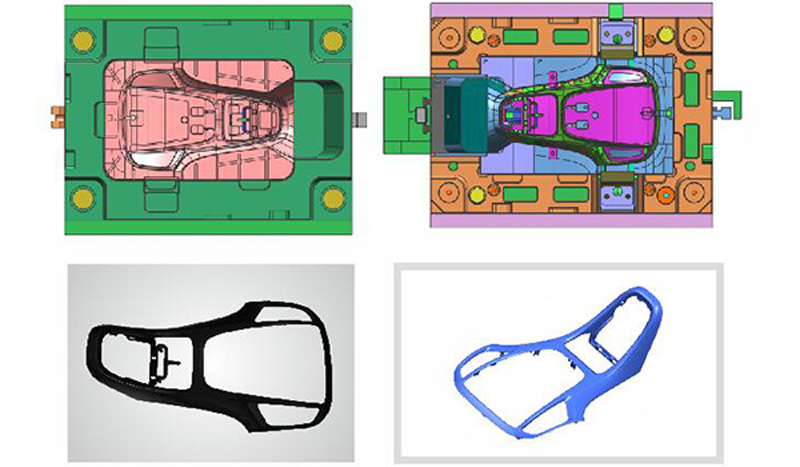

Automotive iziko yokugcina ibhokisi ngundo design show

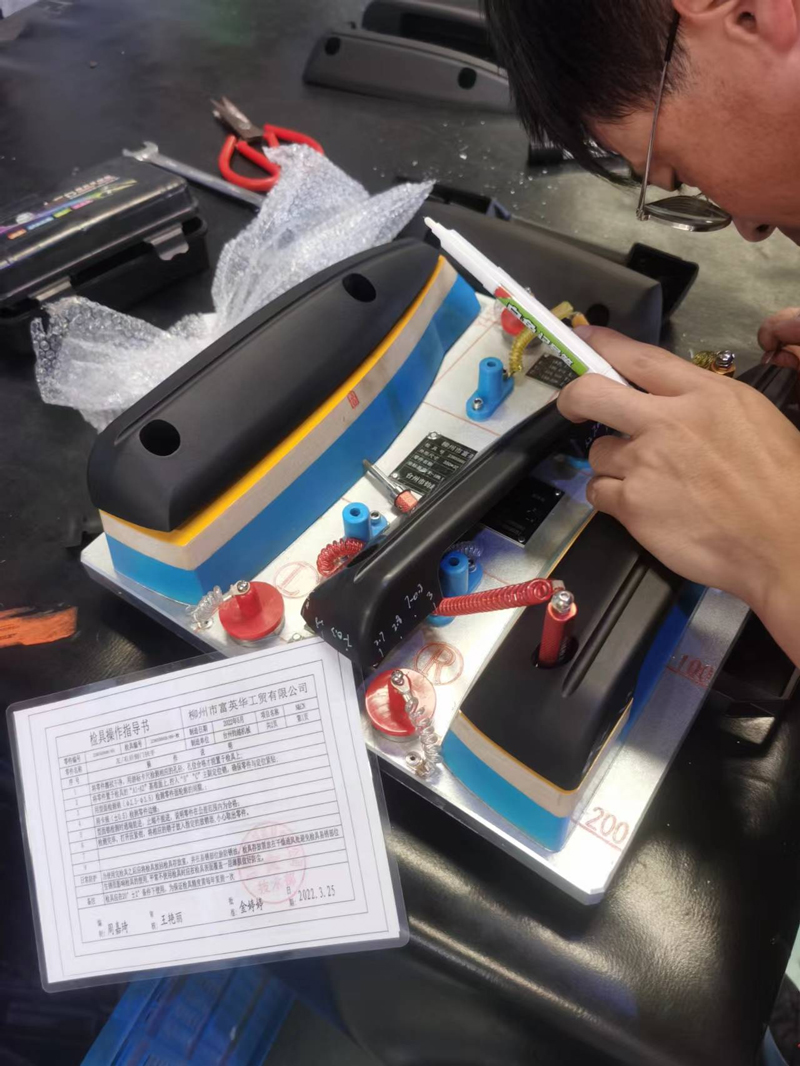

Umngundo we-Sunwin uneminyaka engama-20 yamava atyebileyo kwimveliso yokubumba encediswa yigesi, enokwanelisa ukwenziwa kokungunda kunye nokutofa kweemveliso eziqhelekileyo ezincediswa ngerhasi emarikeni, zihlala zisebenzela umthengi ngomgangatho ophezulu, umgangatho ophezulu, ixesha lokuhanjiswa ngokukhawuleza, kunye ixabiso lokhuphiswano.

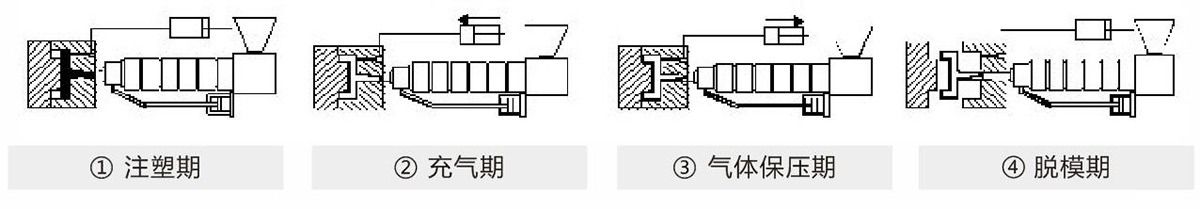

Itheyibhile yomjikelo wenaliti yoncedo lwegesi

Inkqubo yokuncedisa igesi yinkqubo enzima kakhulu.Ngokubanzi, imveliso igcwaliswa kuqala, emva koko igesi ye-inert yoxinzelelo oluphezulu ivuthelwe, i-raw material kwi-semi-molten state ivuthelwe ngaphandle, kwaye igesi isetyenziswe endaweni yomshini wokubumba isitofu ukufumana imveliso.Yiba ngumbumba oncediswa yigesi.

Ukubunjwa kwegesi encediswa yigesi nako kungasombululwa ngeendlela ezingaqhelekanga, ezifana nokufaka i-nitrogen kwi-mold kwi-70% -80% ngokukhawuleza, kunye nokusebenzisa i-nitrogen-assisted molding for the position ezaliswe.Le nkqubo ikwayinkqubo eqhelekileyo kwaye inokusetyenziswa ukuba kuyimfuneko.

Inani leemodyuli kwi-mold-assisted mold is most 1 * 1.Inani lemingxuma yokungunda liya kubangela ukuba irabha okanye umoya wokuthatha ungazinzi.Le nkqubo inzima ukuyilungisa.Xa iveliswa ngokuqhelekileyo, iya kuvelisa izinga eliphezulu le-scrap.Ngoko ke, kuyacetyiswa ngokubanzi.Ubume bemodyuli yomngxuma.Ukuba uyila i-1 + 1 yokubumba i-mold, udinga i-air ints ezimbini ezahlukeneyo zevalve yenaliti enamanqaku amabini.Kufuneka abalawuli ababini abancediswa ngegesi, okuya kuzinzisa imveliso.

umboniso wetyala lokungundo lokutofa ngenaliti yeplastiki yegesi

Inkqubo yokuBumba iSitofu eNcedwa ngeGesi

Ukubunjwa kwenaliti encediswa ngerhasi kwahlulwe ngokwezigaba ngokwezigaba ezi-4: inaliti yeplastiki, inaliti yerhasi, ukupholisa ngokubamba uxinzelelo, kunye nokukhutshwa kwerhasi.

Okokuqala, iplastiki enyibilikayo ifakwe kwi-mold cavity de inyibilike izalise ukusuka kwi-70% ukuya kwi-90% ye-mold cavity.Iqondo lokushisa lokunyibilika liphantsi, kwaye iindonga zombhobho zenza umaleko omncinci wokunyanga.Xa kuthelekiswa nenkqubo yokubumba eqhelekileyo, uxinzelelo olufunekayo lokubumba luphantsi ngenxa yokuba i-cavity igcwele inxalenye kuphela, kwaye umjelo womoya kwi-mold uphinde uququzelele ukuhamba kwe-melted.Ukuba ukunyanzeliswa kokubumba kuphezulu kakhulu kwaye kusetyenziswe izinto ezininzi, kulula ukubangela ukuqokelela kwe-melted kunye neempawu zokucwina kwiindawo ezinezinto ezininzi;ukuba impahla incinci kakhulu, iya kubangela ukuvuthela.

2. Isitofu segesi: Irhasi enomthamo othile okanye uxinzelelo (ngokuqhelekileyo igesi yenitrogen) itofwa kwigumbi.Kweli nqanaba, ixesha lokutshintsha ukutshintshela ukunyibilika ukuya kwisitofu se-nitrogen, kwaye uchaze ngokuchanekileyo uxinzelelo lwegesi, olunxulumene nomgangatho wemveliso, eli nqanaba lingabonakala iziphene ezininzi zemveliso yesitofu segesi, ukulibaziseka okufutshane kukulawula ubukhulu be-condensate. umaleko, lungisa indawo yokuhamba kwegesi, ukupholisa iplastiki yesango ukunqanda ukuhamba kwegesi (ukuhamba kwegesi ukusuka kwisistim yesango kunomjelo womoya osetwe ngaphambili.

3. Ukupholisa uxinzelelo: Emva kokuba i-cavity kunye negesi kufuneka izaliswe ngoxinzelelo oluthile lwegesi, ukusuka ngaphakathi ukuya ngaphandle, ukuqinisekisa ukuba indawo yangaphandle yemveliso isondele kwindonga yokubumba;kunye nokungena kwesibini kwegesi (igesi iyaqhubeka ngaphakathi kwiplastiki yangaphakathi), ukwenza ukunyanzeliswa kokupholisa kwangaphakathi kwemveliso, ukukhuselwa koxinzelelo ngokubanzi kubandakanya ukubamba uxinzelelo oluphezulu kunye noxinzelelo oluphantsi olubambe izigaba ezimbini.

4. Ukukhutshwa komoya: Emva kokuba imveliso ipholile ngokuqinileyo kwaye yenziwe, igesi kwindawo kunye nengundoqo inokukhutshwa ngenaliti yokukhupha okanye i-spray, uze uvule isikhunta ukuze ususe umkhiqizo.Kufuneka kuqatshelwe ukuba i-injection yegesi kwinkqubo yokubumba i-gas-assisted injection kufuneka ikhutshwe ngaphambi kokuba kuvulwe i-mold.Ukuba igesi yoxinzelelo ayikhutshwa ngexesha, imveliso iya kwandisa okanye iphule.

Ityala lokungunda lokungunda leplastiki encediswa ngamanzi

1. Ukubunjwa kwenaliti encediswa ngamanzi kusetyenziswa amanzi, ukubumba ukutofa kwamanzi kunokuphinda kusetyenziswe kwaye kusetyenziswe kwakhona, ngoko ke amanzi aphakathi kwezi nkqubo zimbini zokwenza amanzi aphantsi kunenitrogen;

2. Iindleko zesixhobo sokubumba isitofu esincedisayo samanzi siphantse sibe ngama-10 aphezulu kunolo lwenaliti encediswa yigesi.Okwangoku, ukubumba isitofu esincedisayo samanzi kunokungeniswa ngaphandle kuphela;

3. Ukubumba inaliti encediswa ngamanzi ingasetyenziselwa inaliti epheleleyo, hayi ukubumba ngesitofu esifutshane;

4. Ukusetyenziswa kwezixhobo zeplastiki kwinkqubo yokubumba i-gas-assisted injecting isetyenziswa ngokubanzi kunenkqubo yokubumba isitofu sokuncedisa amanzi;